Cataphoretic painting

- Modern, progress type

- The product is a cathode

- Epoxid paints – excellent anticorrosive resistance

- Acrylate paints – very good UV resistance

- Patent: 1978 CHRYSLER France Europe

- Electromechanical painting process – paint is applied on the part surface by use of direct current voltage gradient

- Requirements:

- conductive surface of painted product

- the product must be fully soaked in the painting tank = adjusted product

- preliminary treatment

- resistance to burning temperature of 200 °C

Advantages of cataphoresis during the painting process

- High anti-corrosion resistance while tense layer of paint (in case of use of 25 um of paint the resistance of 1000 hours in salted mist confirmed).

- High penetration – sinus protection.

- Ecological and safe production which Futaba pays attention to.

Components of cataphoretic process

Main paint - cathodic epoxid polymer - corrosion resistance (cca 25 um, 1000h salted mist)

Pigment paste - pigment, mineral additives; paint - shade; rim corrosion resistance, flame resistance; mechanical engine protection

Demiwater - peculiar paint solvent

The summary of paint shop production parameters

| Maximum pass-through profile | 250 mm lenght (move ahead direction) |

| 550 mm width | |

| 1400 mm height | |

| Undercoat material | mild steel |

| Conveyor type | underslung, continual |

| Pitch between hinges | 720 mm |

| Conveyor speed | 2,0 meters / min |

| Net throughput | 167 hinges / hour |

| Average surface for 1 hinge | 1,8 m2 |

| Maximum painted surface | 300 m2 / hour |

| Paint thickness | 25 microns |

| Hinges max. weight | 37 kg maximum |

| Average weight throughput | 4545 kg / hour |

| Loading on 1 m conveyor | 90 kg |

Quality Check of painted parts

- Check of adherence via cross cut test.

- Check of hardness.

- Check in salt mist chamber - 1000 hours (thickness 25um).

- Check by thickness meter.

- Check of paint durability by cloth and/or chemicals.

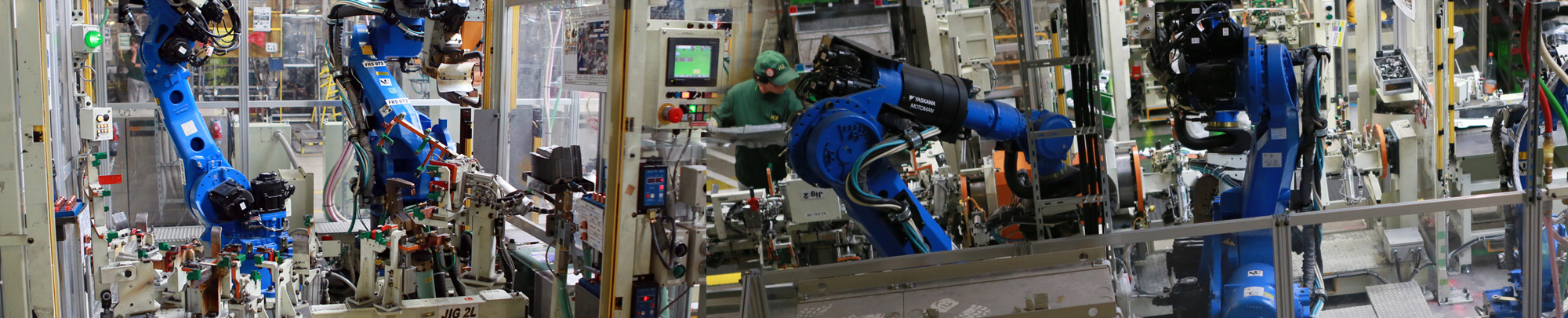

Futaba Czech s. r. o. offers ecological and high quality painting process in the region of Vysočina prefecture in the city Havlíčkův Brod:

- Since 2006 we provide supplies of painted parts to customers such as Toyota, Peugeot Citroën and Suzuki.

- Our main philosophy is to ensure quality and safe products and to satisfy our customers´ needs.

- We offer “quality products at lower cost” not only in process of welding and press but also painting.

We are prepared to reply to your enquiries on our telephone number: (+420) 569 496 467 or e-mail address sales fcz.cz.

fcz.cz.